LG Warehouse Installation

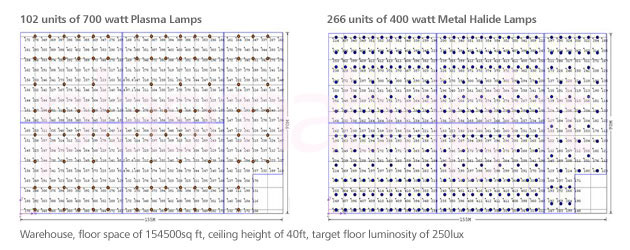

LG undertook the installation of the plasma lighting systems in a new warehouse located in Yangsan, South Korea. The warehouse had dimensions of 515ft x 300ft for a total floor space of 154500sq ft and had a ceiling height of 40ft. The target floor lumination was 250 lux. The lighting simulation showed a requirement of 266 units of 400 watt metal halide lamps or 102 units of 700 watt plasma lamps, model PSH0731B to achieve the illumination targets. After doing a site inspection and cost analysis, the decision was made to go with plasma lamps for the superior colors, immense cost savings and even illumination.

Luminaire Positions

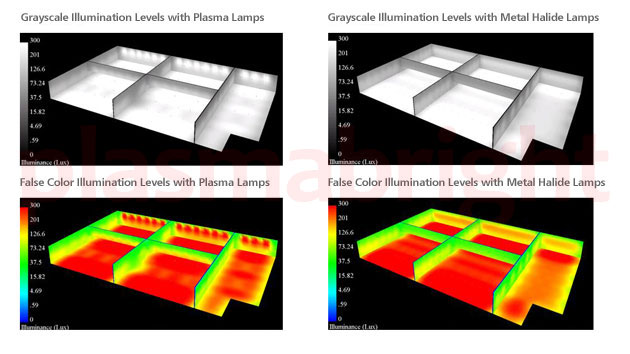

Simulated Illumination Levels

Initial Fixed Costs

| 400w Metal Halide Lamps: | 700w Plasma Lamps: | ||||||

| Part | # of Units | Cost | Total Cost | Part | # of Units | Cost | Total Cost |

| Bulb | 266 | $50 | $13300 | Luminaire | 102 | $1500 | $153000 |

| Ballast | 266 | $60 | $15960 | ||||

| Fixture | 266 | $100 | $26600 | ||||

| Subtotal | $55860 | Subtotal | $153000 | ||||

| Installation Labor Costs | 266 | $50 | $13300 | Installation Labor Costs | 102 | $50 | $5100 |

| Initial Cost | $69160 | Initial Cost | $158100 | ||||

Installation labor costs is calculated at $50 per fixture, which takes into consideration the time to install, lift equipment and the wiring involved in installing these fixtures. Initial fixed costs came out to be $158100 for the plasma lamps compared to $69160 for metal halide lamps, a difference of $88940. The cost of plasma lamps might seem high at first, but keep in mind energy costs and maintenance costs are far more important and that's where you'll see the tremendous savings with plasma lamps, as shown in the charts below. Note, the plasma fixtures prices are high estimates and are available at a lower price. The metal halide lamps are current retail prices.

Energy Costs

| 400w Metal Halide Lamps: | 700w Plasma Lamps: | ||

| Watts per Fixture | 460w | Watts per Fixture | 730w |

| Color Rendering Index | 60~65 | Color Rendering Index | 80~85 |

| # of Units | 266 | # of Units | 102 |

| Power Consumption | 122360w | Power Consumption | 74460w |

| Cost per kWh | $0.15 | Cost per kWh | $0.15 |

| Hours per Day | 15 | Hours per Day | 15 |

| Days per Year | 300 | Days per Year | 300 |

| Annual Power Consumption | 550620kWh | Annual Power Consumption | 335070kWh |

| Annual Energy Costs | $82593 | Annual Energy Costs | $50260 |

| Annual Energy Savings | $32333 | ||

The LG warehouse is a distribution facility and required the lights to be on for 15 hours a day, 300 days out of the year, or roughly 6 out of 7 days a week. The 460w figure for the metal halide lamps include the power used by the ballast. The annual energy savings is obvious with plasma lamps. A total of $32333 is saved annually, which pays off for the price difference in the initial fixed costs within 2.7 years. But wait, there's more! Plasma lamps require less maintenance because the bulbs do not dim with age and the parts last longer, see the below chart for details.

Maintenance Costs

| 400w Metal Halide Lamps: | 700w Plasma Lamps: | ||

| Bulb Life | 10000 hours | Magnetron Life | 30000 hours |

| Ballast Life | 30000 hours | ||

| Hours on per Year | 4500 | Hours on per Year | 4500 |

| Hours per 10 Years | 45000 | Hours per 10 Years | 45000 |

| Bulb Replacements in 10 Years | 4.5 | Magnetron Replacements in 10 Years | 1.5 |

| Ballast Replacements in 10 Years | 1.5 | ||

| # of Bulbs Replaced | 1197 | # of Magnetrons Replaced | 153 |

| # of Ballasts Replaced | 399 | ||

| Replacement Parts Cost | $83790 | Replacement Parts Cost | $45900 |

| Bulb Replacement Labor Costs | $29925 | Magnetron Replacement Labor Costs | $3825 |

| Ballast Replacement Labor Costs | $9975 | ||

| Ten Year Labor Costs | $39900 | Ten Year Labor Costs | $3825 |

| Ten Year Parts Cost | $83790 | Ten Year Parts Cost | $45900 |

| Ten Year Energy Costs | $825930 | Ten Year Energy Costs | $502600 |

| Ten Year Total Operating Costs | $949620 | Ten Year Total Operating Costs | $552330 |

| Annual Total Operating Costs | $94962 | Annual Total Operating Costs | $55233 |

| Annual Total Savings | $39729 | ||

| Price Difference Payoff Time | 2.23 Years | ||

Though metal halide bulbs might be rated for 20000 hours, lumen depreciation within the first 10000 hours drops by 30%. Bulb orientation can also have a substantial effect on the bulb life and brightness. We used a figure of $25 per part replacement for the labor costs. Once we factor in the maintenance costs, the savings are even greater. Total costs to operate the plasma lamps annually is only $55233 compared to $94962 for metal halide. This is an annual savings of $39729, which means the initial price difference of $58340 between plasma and metal halide will be paid off in just 2.23 years!

Keep in mind these energy costs are calculated under the assumption energy prices remain the same during the 10 years. History has proven that energy costs will always rise with time so the payback time might be quicker than the figures shown above. 1197 metal malide bulbs and the 60000mg of mercury that those bulbs would have contained were saved from the landfills by going with plasma lamps. Note the lower color rendering index of 60~65Ra with the metal halide lamps compared to 80~85Ra with the plasma lamps. The savings and benefits are obvious.

Picture of Final Installation